Introduction to Six Sigma

Six Sigma is a rigorous, data-driven methodology aimed at improving the quality and efficiency of business processes. Originating from Motorola in the 1980s, Six Sigma has since been widely adopted across various industries to minimize defects and variability in processes, thereby enhancing overall performance.

Core Principles of Six Sigma

Six Sigma revolves around five core principles, often summarized by the acronym DMAIC:

- Define: Clearly define the problem, goals, and customer (internal and external) requirements.

- Measure: Accurately measure the current process performance.

- Analyze: Identify the root causes of defects and inefficiencies.

- Improve: Implement and verify solutions to address the root causes.

- Control: Maintain the improvements and ensure consistent performance over time.

Key Concepts in Six Sigma

- Critical to Quality (CTQ): Attributes most important to the customer.

- Defect: Failing to deliver what the customer wants.

- Process Capability: What your process can deliver.

- Variation: What the customer sees and feels.

- Stable Operations: Ensuring consistent, predictable processes to improve what the customer sees and feels.

- Design for Six Sigma (DFSS): Designing to meet customer needs and process capability.

Benefits of Six Sigma

- Improved Quality: Reduction in process variability leads to fewer defects and higher quality products/services.

- Customer Satisfaction: Consistent delivery of high-quality outcomes enhances customer satisfaction and loyalty.

- Cost Reduction: Efficient processes reduce waste, rework, and operational costs.

- Employee Morale: Engaging employees in problem-solving improves morale and fosters a culture of continuous improvement.

- Competitive Advantage: High-quality, efficient processes give organizations a competitive edge in the market.

Six Sigma and Machine Learning

The integration of Six Sigma with machine learning (ML) can significantly enhance data analysis and process optimization efforts. Here’s how ML can complement Six Sigma methodologies:

- Predictive Analytics: Using ML models to predict defects and process failures before they occur.

- Anomaly Detection: Identifying unusual patterns and outliers in processes that may indicate potential issues.

- Process Automation: Automating repetitive and data-intensive tasks to improve efficiency.

- Advanced Data Analysis: Leveraging ML algorithms for deeper insights into process performance and root cause analysis.

Implementing Six Sigma in Your Organization

- Training and Certification: Invest in Six Sigma training and certification for employees to build a skilled workforce.

- Project Selection: Choose projects that align with organizational goals and have a significant impact on performance.

- Data Collection and Analysis: Utilize robust data collection methods and advanced analytics to inform decision-making.

- Continuous Improvement: Foster a culture of continuous improvement, encouraging employees to identify and solve process inefficiencies regularly.

- Leverage Technology: Integrate machine learning and other advanced technologies to enhance Six Sigma efforts and achieve better results.

Step-by-Step Proccess

- Load Data: The initial step is to load the dataset into the program, making it available for further processing.

- Remove Empty Columns: Eliminate columns that contain no data to streamline the dataset.

- Remove Empty Rows: Similarly, remove rows that are completely empty to ensure data quality.

- Ensure Data Types: Verify that each column’s data type is correct to prevent processing errors.

- Data Quality Check: Conduct a thorough check of the dataset to identify and address any quality issues.

- Impute Missing Values: Fill in any missing values in the dataset to ensure completeness.

- Detect Anomalies: Identify any anomalies or outliers in the data that might affect analysis.

- Pearson Correlation: Calculate the Pearson correlation coefficient to understand relationships between variables.

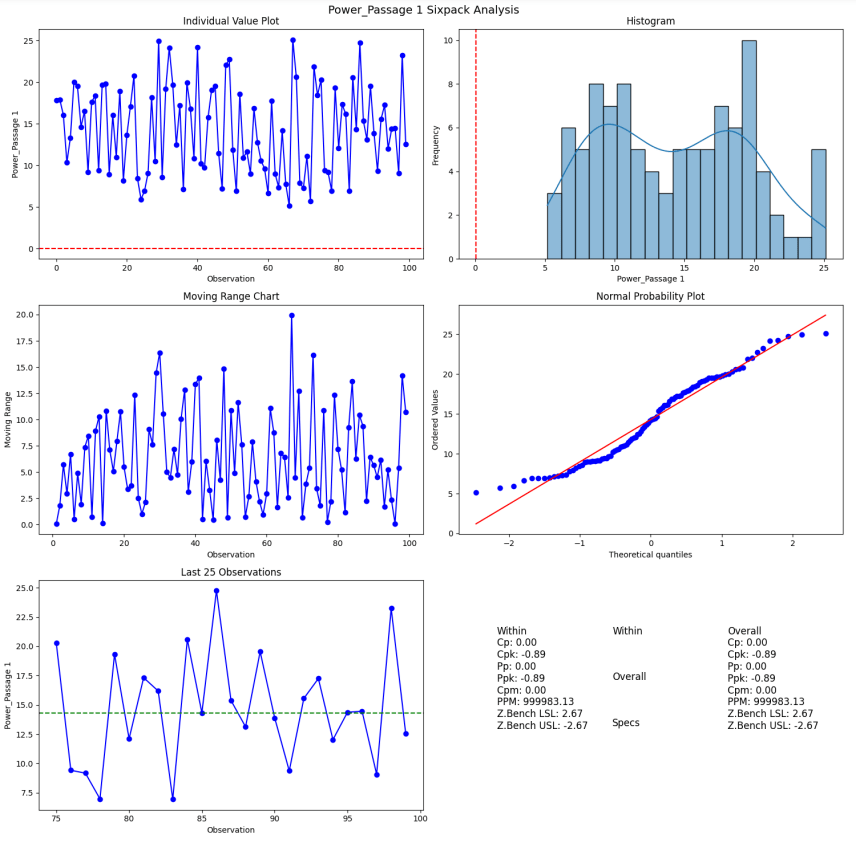

- Sixpack Analysis: Conduct a six-pack analysis to assess process capability.

- ANOVA Analysis: Perform an ANOVA analysis on the target variable to understand variance among groups, specifically by ‘Machine’.

- Regression Analysis: Execute a regression analysis using the target variable and the most correlated column to predict relationships.

- Train AutoML Model: Train a model using AutoML to automate machine learning tasks.

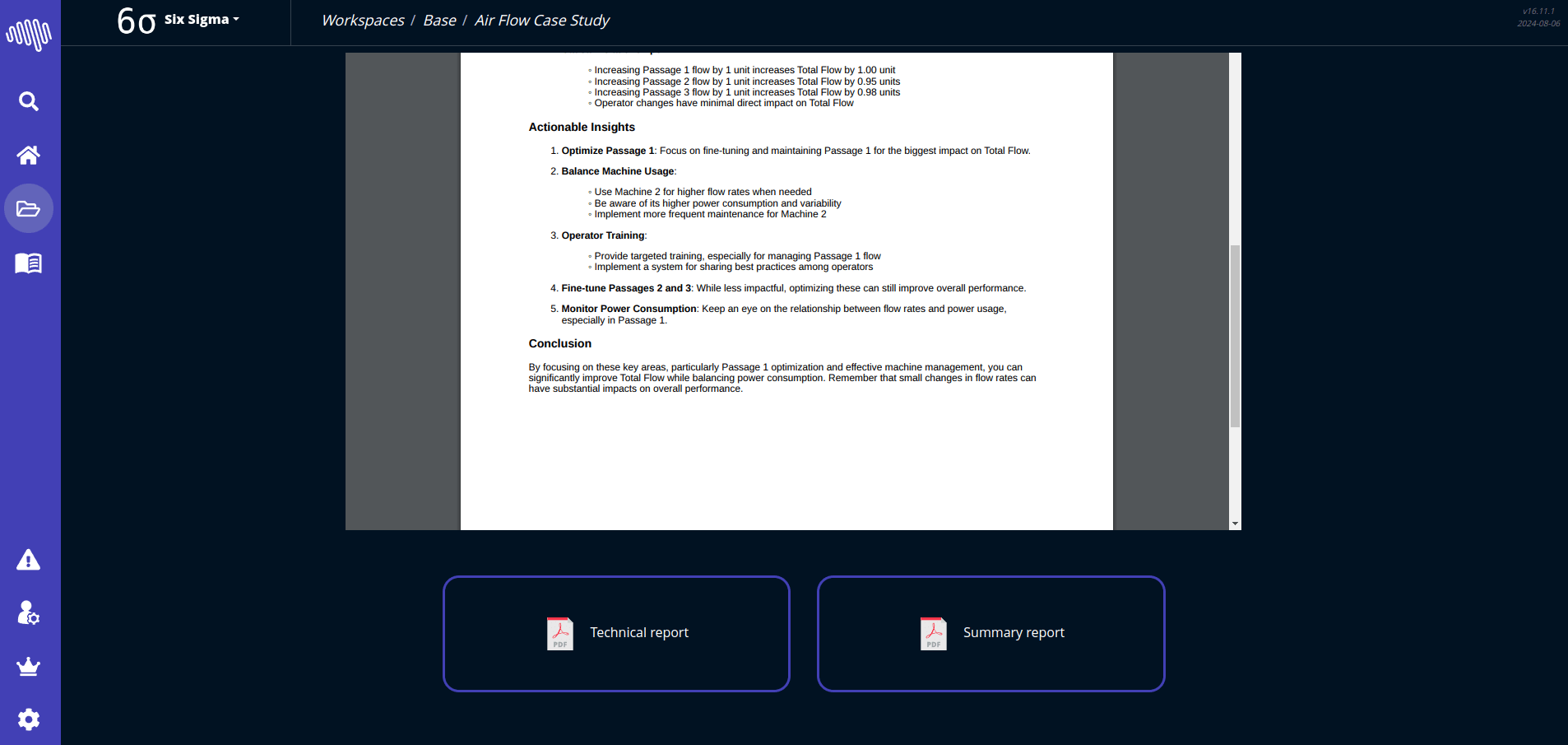

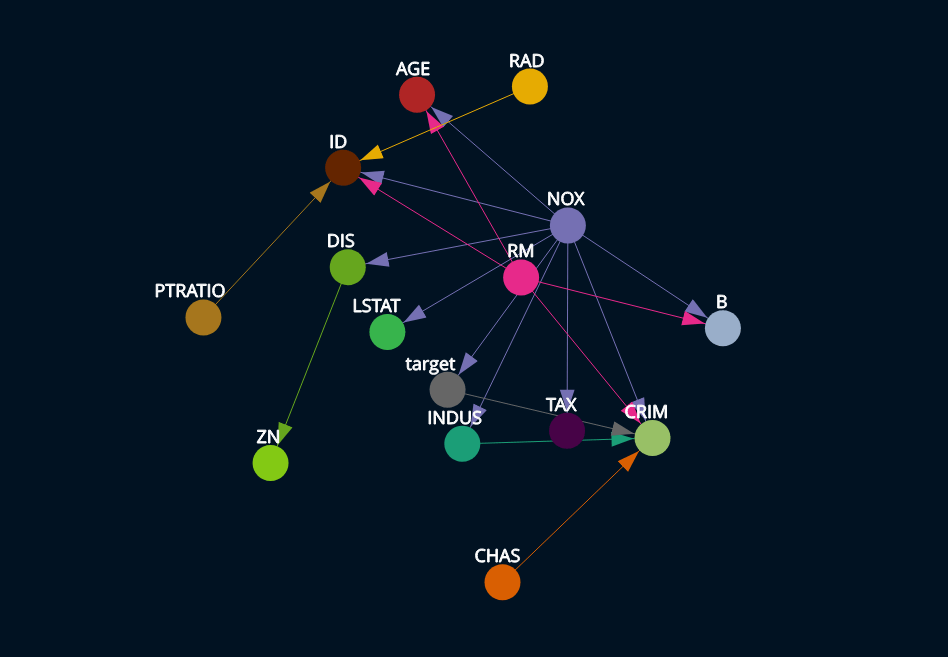

- Causal Inference: Perform causal inference analysis to determine cause-and-effect relationships within the data.

This structured approach ensures a comprehensive data analysis process, from loading and cleaning the data to performing advanced statistical and machine learning analyses.

Conclusion

Six Sigma remains a powerful methodology for process improvement and quality management. By combining Six Sigma principles with machine learning, organizations can achieve even greater levels of efficiency, quality, and customer satisfaction. Embrace the Six Sigma approach to drive your organization towards operational excellence and sustained competitive advantage.